You've got your action camera and you're ready to set up your motorcycle helmet with a chin mount and record your rides. Now, the big question is; what product do I use?

With so many options, it's a tough decision! However, before you consider 3D printed mounting options, you will want to read this.

3D printed mounts are made with less structural integrity. This is because 3D printing is done with small strands of plastic filament stacked on top of each other over and over again. Imagine you're behind a steel wall with a truck on the other side coming at you at a high speed. Would you rather be behind a steel wall that's made up of several strips of steel welded together or a steel wall that was made by melting down the metal to a molten liquid, poured into a mold, and made into one, large, piece with no weak spots or seams? Unlike those 3D printed mounts, our products are injection molded meaning the plastic is melted and injected into a tough steel mold. This means that there's no weak spots in the plastic, no air pockets, nothing. It's the strongest way to produce plastic products. With 3D printed mounts, you're stressing those strands just a little every single day until one day, you find your GoPro tumbling behind you on the freeway. Not only that, but 3D printing PLA filament really does not handle weather well. Due to the method it's made, it's a very porous end-product. That means moisture, heat, dust, etc. are all eating away at that any time that you're in the elements, weakening it until one day it can just crumble apart. Even 3Dprint.com, the self-proclaimed "Voice of 3D Printing" acknowledges this obvious shortcoming saying themselves, " The major disadvantage of FDM-created products is their low quality and structural defects (porosity)". Again, with injection molded products, like MotoRadds Chin Mounts, you're not getting low quality and structural defects like you would with 3D printed products.

With so many options, it's a tough decision! However, before you consider 3D printed mounting options, you will want to read this.

3D printed mounts are made with less structural integrity. This is because 3D printing is done with small strands of plastic filament stacked on top of each other over and over again. Imagine you're behind a steel wall with a truck on the other side coming at you at a high speed. Would you rather be behind a steel wall that's made up of several strips of steel welded together or a steel wall that was made by melting down the metal to a molten liquid, poured into a mold, and made into one, large, piece with no weak spots or seams? Unlike those 3D printed mounts, our products are injection molded meaning the plastic is melted and injected into a tough steel mold. This means that there's no weak spots in the plastic, no air pockets, nothing. It's the strongest way to produce plastic products. With 3D printed mounts, you're stressing those strands just a little every single day until one day, you find your GoPro tumbling behind you on the freeway. Not only that, but 3D printing PLA filament really does not handle weather well. Due to the method it's made, it's a very porous end-product. That means moisture, heat, dust, etc. are all eating away at that any time that you're in the elements, weakening it until one day it can just crumble apart. Even 3Dprint.com, the self-proclaimed "Voice of 3D Printing" acknowledges this obvious shortcoming saying themselves, " The major disadvantage of FDM-created products is their low quality and structural defects (porosity)". Again, with injection molded products, like MotoRadds Chin Mounts, you're not getting low quality and structural defects like you would with 3D printed products.

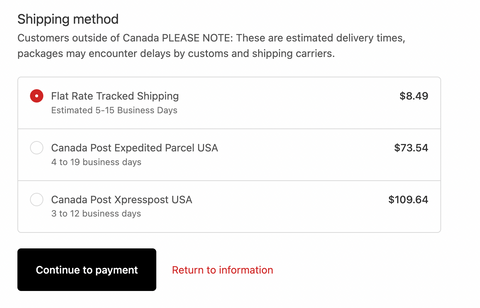

Pricing. The pricing is actually not bad. At least... that's how it looks at first. You pay $20 for a mount which is in the average range of pricing for this market. However, then you realize that it doesn't include the necessary J hook and extension joint. If you want that, it's $5 more. But that's not where the price rising stops. Unfortunately, because this is not an American business and ships from another country, if you're American, you're paying a premium shipping rate of $8.49 and you're waiting 5 to 15 days!

"Well how does your pricing compare?" Glad you asked! Our original mounts are a bit more expensive, however, the price was determined as the cost we needed to charge to fund our pursuits of making an even better product at a lower price. That's how we funded our research and development and creation of the FLEX Mounts line. Our goal was always to offer our products for less than $20 and we are finally able to do so. Our FLEX line starts at $14.99 and maxes out at $19.99! The FLEX Mounts also eliminated bulky buckle clips and now only requires one extension joint which is included in the box so you don't have to shell out any extra money to get your camera setup. It's just plug and go! Oh, and shipping? Because we are an American🇺🇸 business, if you're also in the United States, we ship straight from our warehouse in Arizona and you're only paying $3.50 for a 3-5 day delivery! Our maximum delivery time is faster than their minimum! Our shipments to Canada actually cost us over $11 but we have decided to eat some of those costs so we can provide shipping for only $5 more to our northern friends. This means, with Ride Tech Moto you're out the door for $33.48 for a full setup plus shipping (this is the same price as our original chin mount out the door). With us, you can be out the door for as low as $18.49, that's nearly HALF THE PRICE!

BAD WARRANTY! You can always tell how much a company trusts their product by the warranty they offer. And we offer a lifetime warranty. That's right! LIFETIME. Which customers have loved! We have customers that will email us with a product they bought 4 years ago saying, "I had an accident, the mount got ruined by scraping on the road." No problem. We ask for the old one sent back to us and send out a new one. All at no cost to you! Not even shipping costs!

RideTech Moto, however, isn't so generous with their policy. Their policy states: "All products listed on the website, have a 6 month warranty period that covers any defects. The warranty does not cover any other items that are not purchased from RideTech website." This essentially says that they put their expected product lifespan at 6 months. After that, their products are too susceptible to being warranty-claimed and so this is how they avoid responsibility for a product that is not designed for longevity. Do you trust a product that a company has so little faith in that they have to cap their warranty at 6 months? Especially when the product is made for a few pennies worth of PLA filament? With us, you never have to worry. We stand by our products for life because we know that they are designed to last forever. Not only that, but you're supporting us by using our products so ensuring that you have that product for life is important to us. You shouldn't have to pay every time you need to replace your chin mount because it was made with poor materials and methods. That's just not fair for you or your wallet.

All that being said, the choice is yours. What do YOU trust your action camera with? What do YOU trust to last forever? How many times do YOU feel you should pay for a product if it fails?

All we can say is that we make it our mission to create the best and strongest products and to make sure that when you're using our products, you are taken care of. Always. This article isn't meant to slander anyone, but to educate on why 3D printed products aren't as secure, why pricing can be misleading, and what the fine print warranties could mean when you read between the lines. We believe education is key to make informed decisions that are best for you and your wallet!

1 comment

On the first look you can indeed see that the quality is low. Can not say for sure but it looks like the structural strenght is low. Also the promised deliverytime is way of. It is best to order a chinmount 3 months in advance before you really need it. It was on an airport for almost more then one month while nothing happenend. The status stayed the same. So i did not receive it on time for my two month long motorcycletrip. One week after i came home. That was a big bummer. Had to film from the handlebar but the windshield was in the way. After a week left the Insta360 in the case. There was no purpose to make video behind a dirty windshield. Also the vibration ruined the video. So paid 600.00 Euro for a actioncam and other stuff. But with no way to use it properly. Wished i had that money added to buy a new S23 from Samsung.